By Joannes Vermorel, Neil Addison, Estelle Vermorel, May 2022Copacking or

co-packing[a], is the process of packing products together. The term contract packaging is also used when this action is outsourced to an external company, known as the copacker or contract packager. The copacker is then contracted to assemble, package, and in some cases, even warehouse and distribute the finished product. The result is a product that is ‘

shelf-ready ’ for the retailer to sell. However, copacking is largely done internally by companies that operate at scale, through dedicated business units.

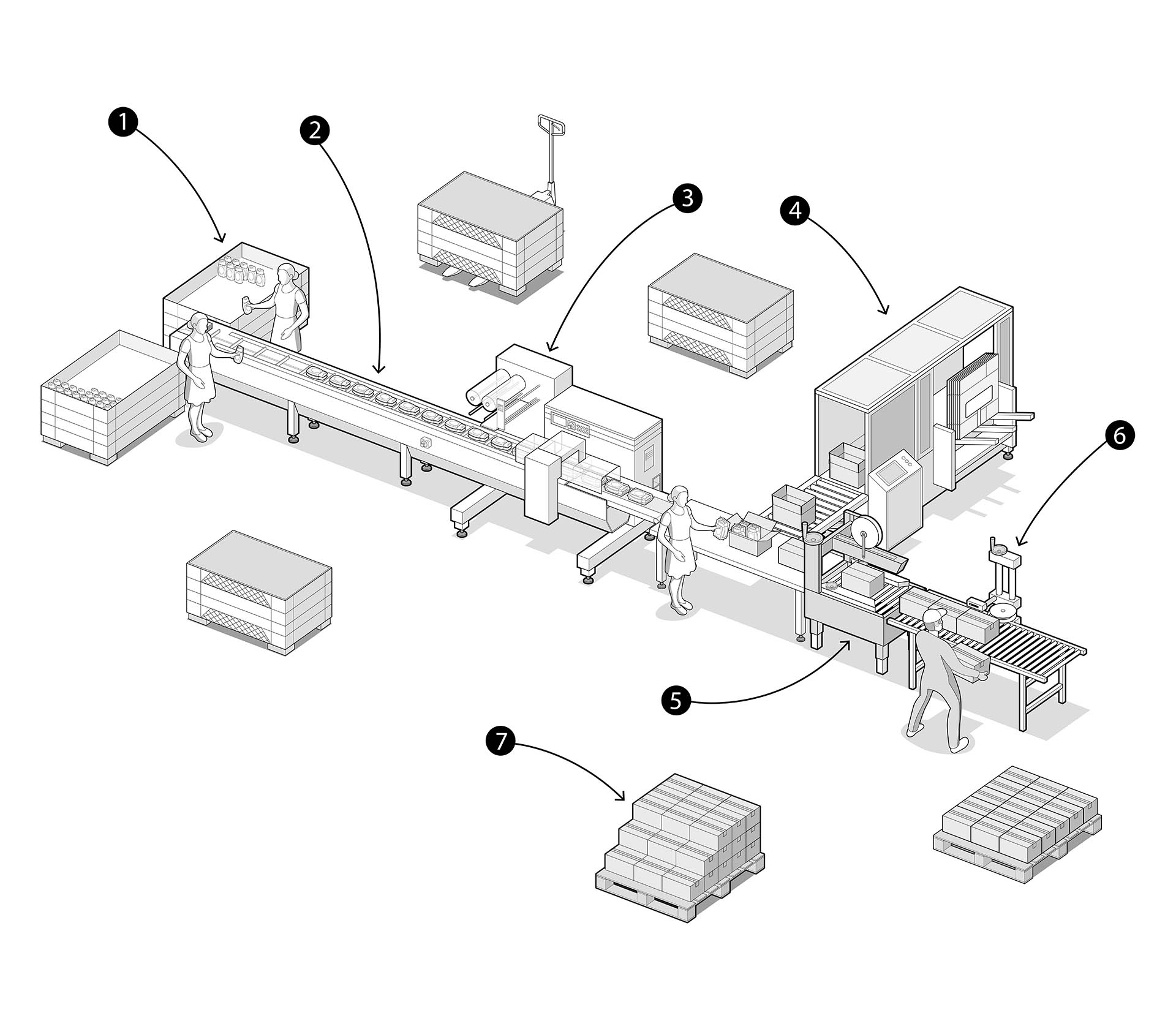

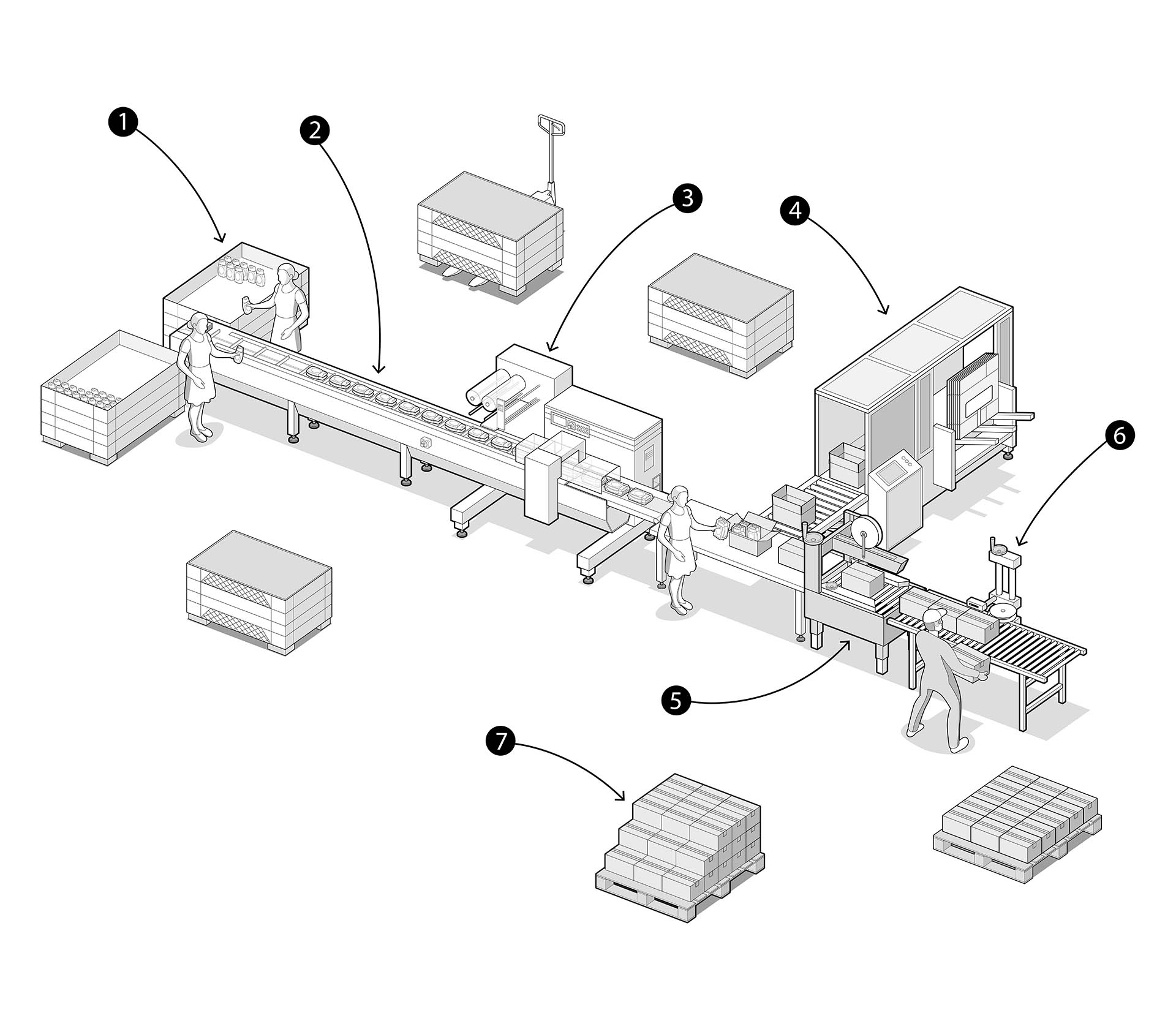

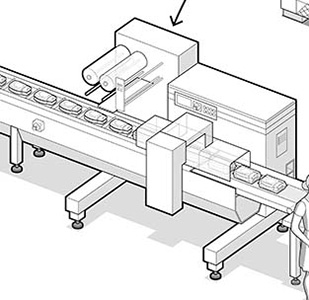

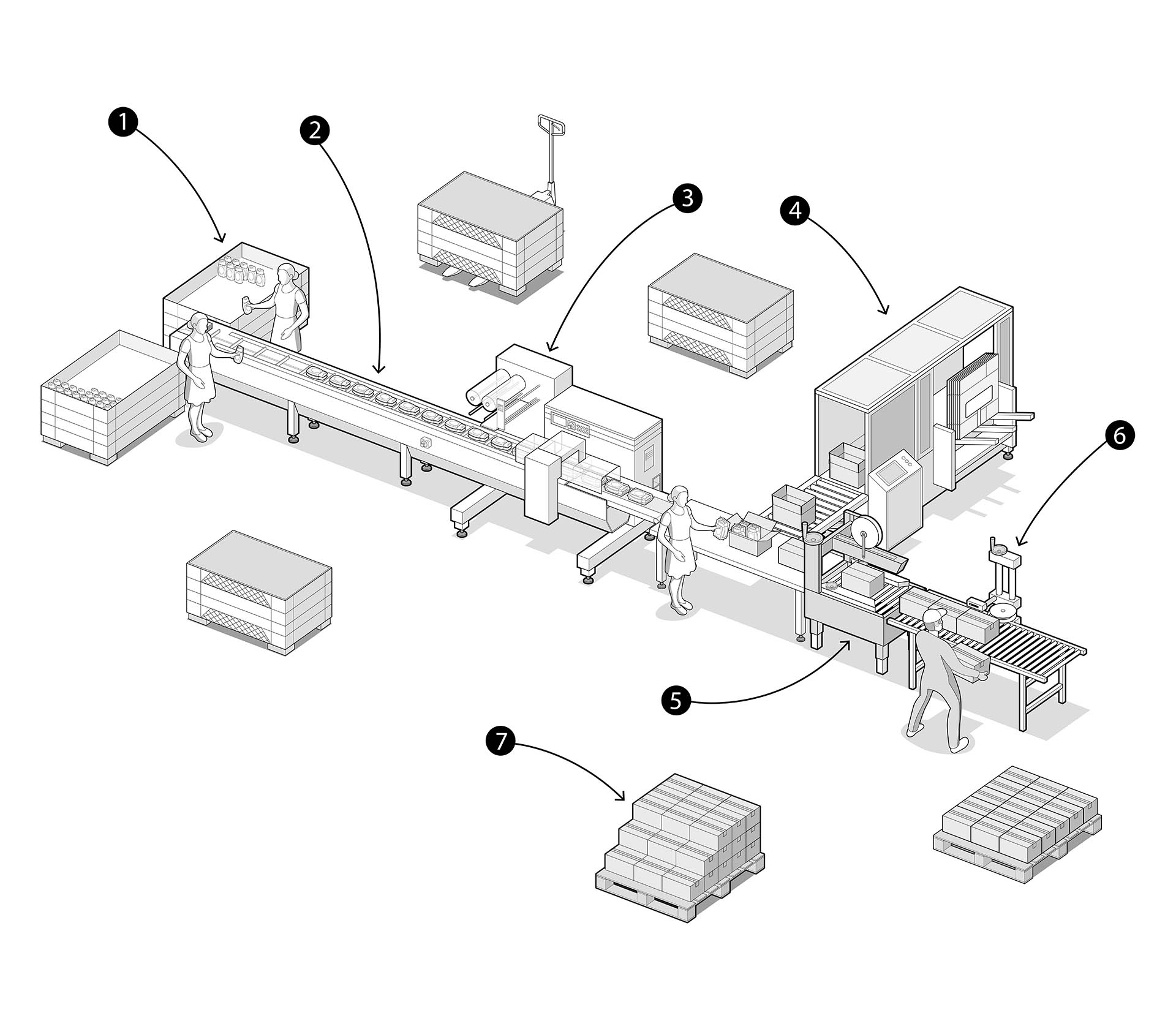

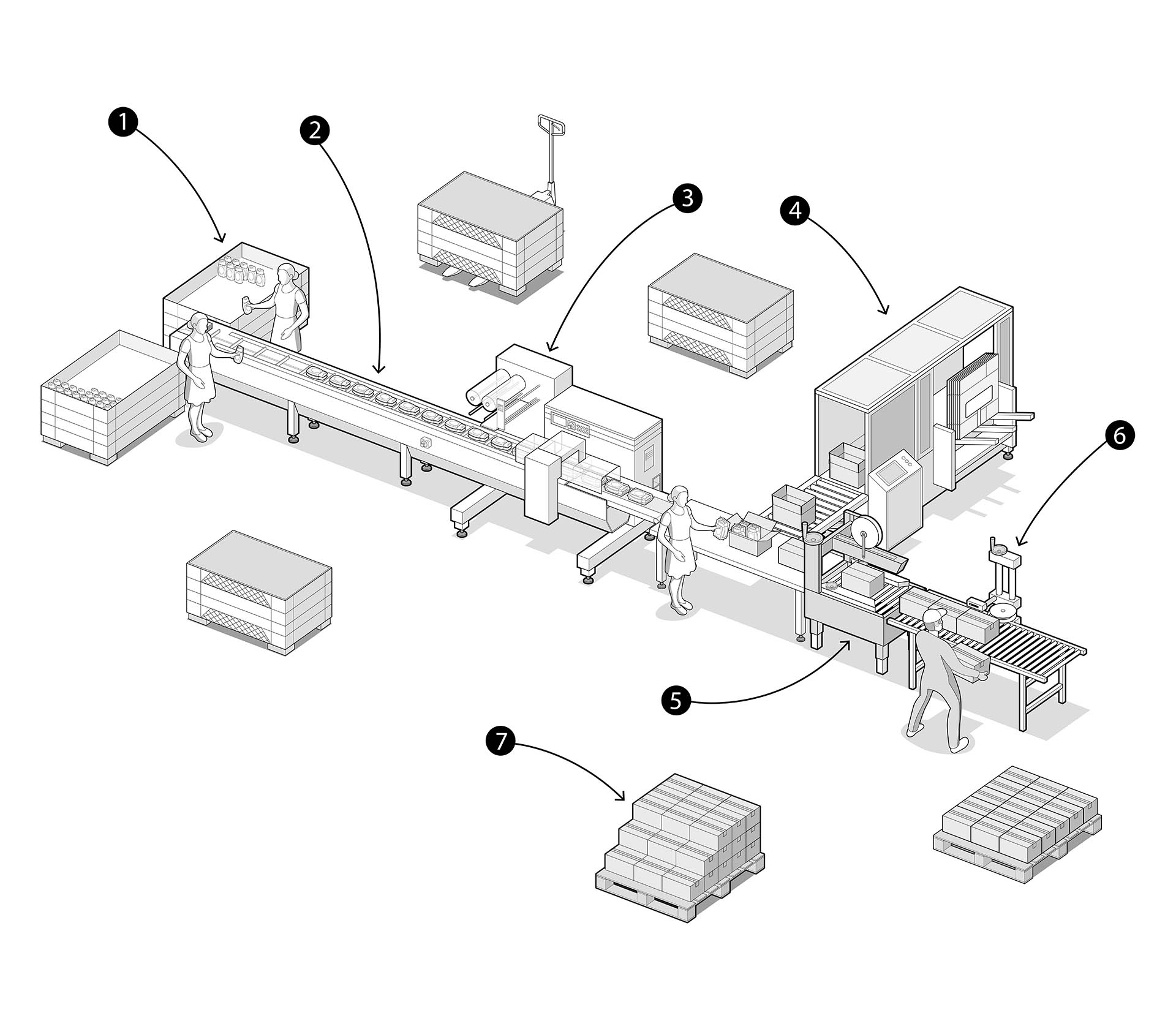

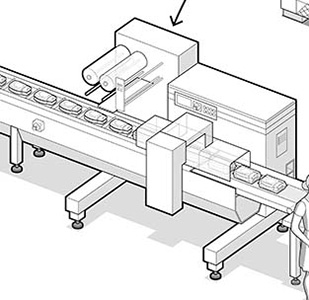

Figure 1: A copacking production line showing the individual steps in the copacking process, and the machines used. (1) Inbound pallet boxes, (2) Belt conveyor system, (3) Shrink wrapping machine and heat shrink tunnel, (4) Box forming machine, (5) Box sealing machine, (6) Label printer applicator, (7) Outbound wooden pallets. Further details of the individual steps can be found below.

Copacking has two very distinct perspectives: marketing and logistics. In terms of marketing, it enables increased visibility of products through seasonal packaging, promotional sets, multipacks, or by featuring a main product with a sample included. Copacking is even at the very center of some new markets, for example the recent trend of subscription boxes (e.g., for monthly selections of beauty products, clothes, DIY, etc.). In terms of logistics, copacking can allow a reduction in lead times, ease the logistics of putting the products in aisles directly from the pallets, and, particularly when externalized to pure players, it can also allow entire classes of complexity to be avoided.

Hypermarkets selling general merchandise are the biggest consumers of copacking (mostly performed internally by the hypermarket brand), but copacking is also widely used in many verticals such as beauty and cosmetics, medical and pharmaceutical, and the food and beverages industries, amongst others. The global copacking market is a growing one that was worth roughly $50 billion in 2020 and is expected to almost double by 2026.

[1] This tendency has also been encouraged by the Covid-19 pandemic which allowed this market to flourish.

From

turnkey to

tolling, copacking services are relatively varied. Services from specialized copacking providers can be quite extensive, from designing the packaging (whether that be blister packs, shrink wrapping, liquid dispensing packaging, etc.), to laminating, folding flyers, printing and attaching labels or barcodes to products, dry/liquid filling, or kitting.

Marketing and brand awareness

Figure 2: A standalone copack structure (right) displaying individually sold cosmetic products, such as nail polish.

The main goals of copacking are to improve brand awareness and capture market share. The purpose is always to ensure an improved display of products, for what marketing professionals like to call “a unique customer experience”, in order to give the product more visibility or to have customers rediscover a product. In that regard, two main categories of copacking can be differentiated.

In the first category of copacking, products are packaged together at the copacker facility to then be distributed to the retail store inside a

shelf-ready (or

retail-ready) package, in which the items will be sold individually. This is particularly useful for seasonal copacking, which provides an opportunity for a special display. An example of this could include a standalone unit for Easter, composed of a display in the style of a small farm which holds an assortment of chocolate Easter eggs (which can be bundles themselves). This entire unit would be shipped as one piece and displayed as is, and customers are then able to purchase one product from the unit. The advantage here is that it facilitates the display in the retail store, and produces a special effect inside the store to maximize attraction. It can be used for seasonal packaging, or special promotions, sometimes with relatively large displays (e.g., gondolas

[b], arches, etc.).

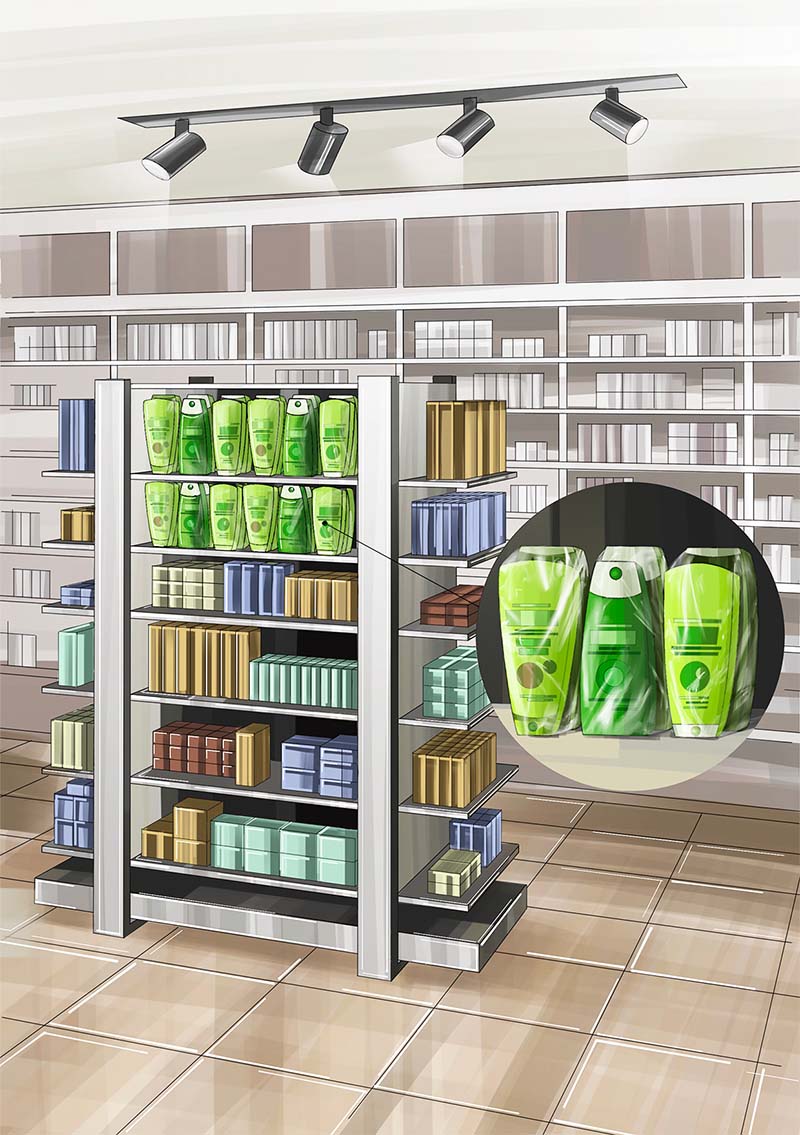

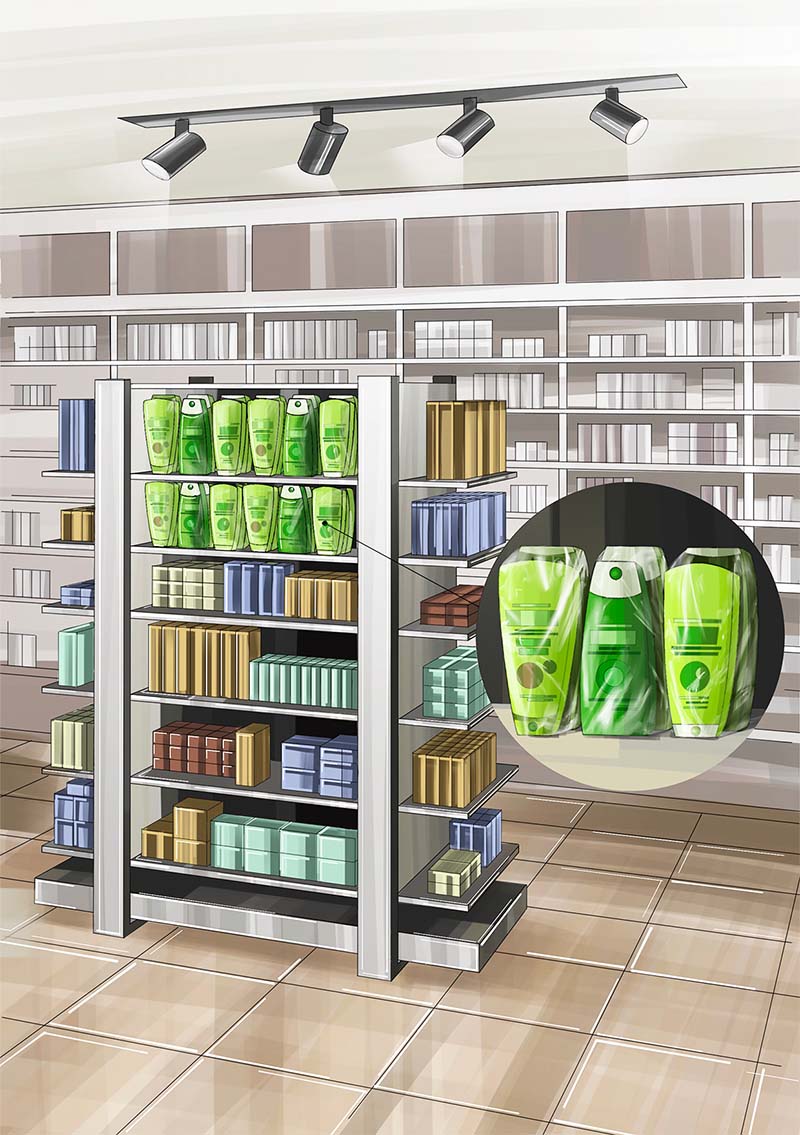

Figure 3: A copack on a retailer’s gondola consisting of a shampoo bottle and a conditioner bottle packaged in a plastic shrink-wrapped sleeve.

In the second category, products are assembled in a single

bundle or kit, but cannot be separated (e.g., a toolkit with screwdrivers, pliers etc., a set of shampoo bottles with a three for the price of two special offer, etc.). This can be found throughout the year and is the most common method of copacking. This is typically used for promotional sales of different products in the same batch, which then become a single sales unit identified by one bar code. This will also often require the promotional offer to be printed onto stickers or other marketing materials. This can help get rid of overstock or can simply help refresh the image of a product for renewed attractiveness. A new package can offer the opportunity for the customer to “

rediscover” the product.

Copacking is a useful tool not only to increase product and brand visibility for existing products, but can also help to push a new product forward, for instance, through samples coupled with a well-established product. An example of this could be a small bottle of a new moisturizer attached to a bottle of face serum. This increases visibility by allowing the customer to try out the new product without making an extra investment. This also presents an opportunity for the manufacturer to lower the financial risk that the company is exposed to. Products of a certain quantity can be produced and tested without investing large sums of money in buildings, equipment or employees, especially if the copacking is outsourced. Once the product has proven successful, the manufacturer may decide to invest more heavily. This test, known as a

line trial, is primarily useful for a small sample-size, but it can also be useful for products of a limited production run.

Logistics and cost reduction

There are also benefits in terms of lead times and cost reduction. Ingredients or parts of the future copackage can be shipped in an optimized way from different suppliers to a copacking facility where the future finished product will be assembled. Cost reductions come from reduced freight and transport costs: moving products between warehouses during packaging and distribution can raise the freight bill by almost 40%.

[2] Delegating the copacking to a dedicated facility rather than doing it at a store level can allow for obvious cost optimization in terms of labor and warehousing, saving space, etc. Furthermore, making the copacked products

shelf-ready can offer a huge gain in terms of logistics for the stores.

Additionally, copacking can be outsourced entirely. External copackers already have the facilities in place in terms of staff, equipment, and expertise, meaning that the manufacturer or retailer is not required to invest in packaging machines, or dedicated and trained staff. For companies that do not operate at scale, it is estimated that the operational costs can be reduced by as much as 7% to 9% by outsourcing packaging activities to contract packagers through the decreased costs of machines and labor.

[1]Operating and supervising a copacking facility requires a certain time commitment, a further point of friction is introduced where the company has to manage yet another team with yet another set of processes. Contracting a copacker to oversee this process will allow the company to focus more on other areas of the business, such as marketing of the products. Copackers will often have the facilities to store components, ingredients and the finished product, as well as shipping and distribution capabilities. The professional expertise and resources extend beyond in-house equipment and required staff. Copackers will be familiar with regulatory requirements and traceability, which may be particularly important for the food, drinks and cosmetics industries which often have stringent regulatory requirements. Furthermore, these requirements can change frequently and rapidly, making it difficult for smaller players to keep up.

Details of the copacking line

Figure 4: A copacking production line.

A copacking production line consists of several steps and several individual machines. These machines are relatively low-tech, and can be bought inexpensively, or even rented should more flexibility be required. The individual devices will often be on caster wheels meaning that moving them into position and setting up the copacking line can be quick and easy. Several employees will also be required for the manual steps involved, which normally consists of moving the products or finished copacks.

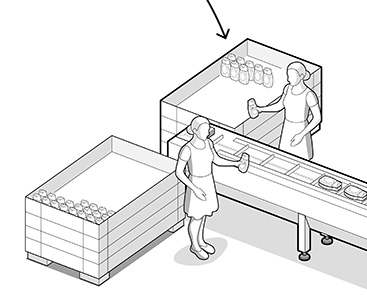

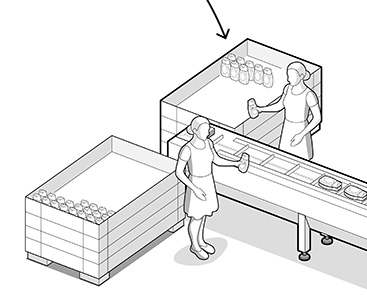

Inbound pallet boxes – The products are placed in pallet

boxes (see Figure 5), not to be confused with regular wooden pallets, by the fast-moving consumer goods company (FMCG) at their production facility. These boxes are often made from plastic and can be stacked when fully loaded, saving warehouse space, and can be moved easily to the copacking line.

Belt conveyor system – An employee will manually arrange the individual products into a bundle and place them on the conveyor belt. They will then be moved towards the next machine in preparation to be shrink wrapped.

Figure 5: Inbound pallet boxes filled with individual items.

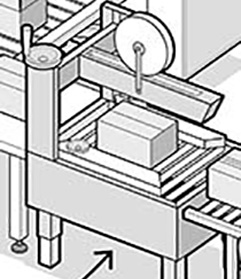

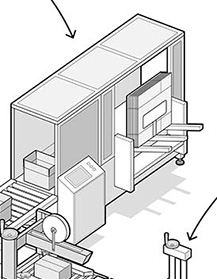

Shrink-wrapping machine and

heat-shrink tunnel – The products approach the shrink-wrapping machine where they are wrapped in the shrink wrap material, normally low-density polyethylene (LDPE). In the example (see Figure 6), there are two rolls of LDPE, but one roll is also possible. The shrink wrap is then cut either with a hot or cold knife. The bundled products then pass through the heat shrink tunnel, causing the LDPE sleeve to contract and conform tightly to the contours of the products. There are several ways in which this process can work including infrared and steam, but the most common type is a recirculating shrink tunnel. Here, regular heating elements are used along with electric blowers to recirculate the hot air.

Figure 6: A shrink-wrapping machine and a heat-shrink tunnel.

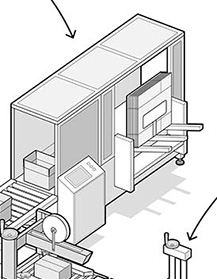

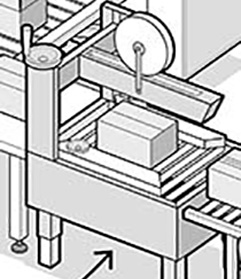

Box forming machine – Flat sheets of pre-cut cardboard are fed into this machine (see Figure 7) and then folded into the correct shape. Additional cutting, hole-punching and gluing of the cardboard are further possibilities. This machine sits perpendicular to the production line and moves the completed boxes towards the main conveyor belt. Another employee will then place the shrink-wrapped copacks into the box, ready for sealing. Multiple copacks are often packaged in the same box, meaning the retailer is forced to purchase a large quantity of the products, normally several weeks’ worth of consumption. This removes the incentive for the retailer to split the copack should any promotions be applied, such as ‘

Buy One, Get One Half Price’, benefitting financially as a result. In order to quickly get rid of what is essentially overstock, the retailer will be obliged to keep the products as a copack with the intended promotion. This has the added benefit of more of the manufacturer’s brand on the retailer’s shelves increasing visibility, at the expense of competitors.

Figure 8: A box sealing machine.

Figure 7: A box forming machine.

Box sealing machine – Sometimes known as a carton sealing machine (see Figure 8), this device quickly and efficiently closes the box lid and applies packing tape to the lid flaps as it passes through. These machines are adjustable, sometimes automatically, to fit different sized boxes.

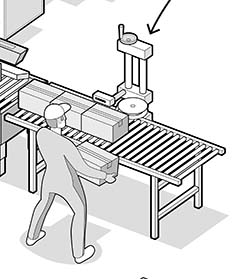

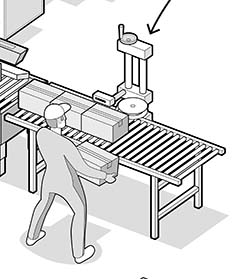

Label printer applicator – A print-and-apply system, sometimes called a wipe-on label applicator (see Figure 9), is a commonly used machine for copacking. A single machine is able to print an adhesive label and apply it to the boxes as they pass through. This label typically contains the barcode and shipping information. In order to prevent label distortion, this type of machine requires speed synchronization between the conveyor belt and label printing machine. Once the label is attached, the box will move forward onto a gravity roller conveyor.

Figure 9: A factory employee removing a box from a label printer applicator.

Outbound wooden pallets – As a final step, once the boxes have been filled with the copacks, sealed and labelled, another employee will manually load the boxes onto cheap, reusable, repairable wooden pallets. They are then ready for shipment to the retailer.

Supply Chain integration of copacking

A growing trend

The global contract packaging market was worth $26.54 billion in 2016, growing to $49.89 billion in 2020, with projections of $47.28 billion in 2022

[3] and $89.74 billion by 2026, registering a compound annual growth rate (CAGR) of approximately 10.18% between 2021 to 2026.

[1] The North American contract packaging market alone is projected to reach $16.35 billion by the end of 2022.

[4] In Europe, according to the

European Co-Packers Association (ECPA), 81% of copackers experienced growth between 2016 and 2018, and 30% are planning to invest in several packaging lines in the next three years.

[5]The copacking market is a relatively fragmented one because copacking facilities do not require large investments to be set up, hence many small players. For instance, there are around 1,000 active copackers in Europe.

[5] Consolidation is likely in the coming years as the best copackers will increasingly offer application programming interfaces (API)

[c] for digital integration in the supply chain. While copacking requires minimal physical investment cost, digital copackers of the future will probably invest significant amounts of money into software and digital infrastructure.

Choosing a contract packer

Copacking services can be broken down further into smaller subcategories which can make the selection easier. Some contract packers receive the specifications (i.e., a formula or recipe) and the custom packaging from the FMCG or retail company; this is known as

tolling. A tolling copacker will receive everything from the company including the specifications, ingredients/components and the packaging, but they will provide the machines and labor.

At the opposite end of the spectrum,

turnkey copackers are responsible for making the complete product. The design of the package can then be left entirely to the copacker. This is more prominent for complex or impressive copacking structures, for example, a mini winter chalet in a hypermarket. Private label copackers can also provide their own formula but allow the manufacturer to put their labels on the final product.

Finally, there are contract packagers who only handle secondary packaging (e.g., a shampoo bottle and a conditioner bottle packaged inside a sleeve).

The choice of a copacker also depends on location, regulations, certifications (especially for food and perishable goods which can necessitate certain storage or transportation requirements), delivery times offered, and as with many businesses,

minimum order quantities (MOQs).

How Lokad can help

Copacking is widely used, and for good reason, but it is a mixed blessing as far as the supply chain is concerned. While it does have its benefits, it also creates analytical difficulties related to inventory replenishment, both at the store level and at the warehouse level.

When it comes to copackages where items can be sold separately, the high granularity of replenishment creates complexities for the quality of service. A variety of products are pushed to the store together in one unit, but inside that unit, the most popular items will be purchased more often, leaving the rest partially empty. Consider a copack stocked with mugs printed with individual first names: the structure itself is purchased by the retailer as one, but inside, the in-demand ’

Michaels’ and ’

Marys’ will sell quickly, potentially leaving the ’

Janets’ and ’

Stewarts’ behind. In the end, this might alter the quality of the display perceived by the customers, as well as create some frustration if they liked the product but couldn’t find their own names. This illustrates the need for the copacking to be balanced so that all the products go out of stock around the same time, meaning the copack structure can be removed from the store at the end of the sale or season.

When it comes to copackages where items cannot be sold separately, there is a different challenge. In this situation, the manufacturer or retailer can modify the content of their bundle as they see fit. This presents the temptation of adjusting the bundle based on what is currently in stock, and perhaps using more of one particular product to get rid of overstock. Take the example of a cheese platter; if the manufacturer has an excess of Brie, they may have the inclination to modify the bundle to contain 40% of that particular cheese. This may seem like a good deal from the retailer's point of view of, but it makes the platter less attractive to customers in search of variety. The same can be said for bundles containing products with different use-by/sell-by dates. Customers do not like imbalance. Copacking should be used alongside the aim of balancing stock. Pushing a little bit more of what is in excess is fine, but it should be kept moderate so as not to be perceived negatively by the client.

These problems, statistical and analytical in nature, are particularly difficult to tackle with mainstream point of sale systems (POS),

enterprise resource planning systems (ERP), and warehouse management systems (WMS), but that’s where Lokad comes in. The programmatic Lokad approach and the flexibility offered by Envision can help find the balance. This reduces the likelihood of quality-of-service problems for the first type of copacking, as well as finding the right balance for the second type, making the most of the available stock, and taking different use-by/sell-by dates into account. All of this can be achieved while preserving a degree of attractiveness.

References

1. Contract Packaging Market – Growth, Trends, Covid-19 Impact, and Forecasts (2022 - 2027), Mordor Intelligence

2. Co-packing: The complete guide, Bennet (Retrieved May 2022 from bpkc.com)

3. Global Contract Packaging market – By Packaging, End Users, Regions – Market Size, Demand Forecasts, Industry Trends and Updates (2016-2022), Research and Markets

4. North America Contract Packaging Market – By Services, Vertical, Country, Trends, Forecasts (2017-2022), Mordor Intelligence

5. European Co-Packers Association (ECPA) market report 2021

a. Both spellings are used, however, more recently the unhyphenated spelling has become more common, likely due to an emergent, unconcerted marketing push from many copackers.

b. A gondola, in the context of a supermarket, is a standalone structure used by retailers to display products and is usually put at the end of aisles. Copacks are frequently stocked on gondolas.

c. An application programming interface (API) is a form of software interface that facilitates a connection between computers or computer programs.